What we do

Production is carried out on modern CNC machining centers and conventional machinery by turning, milling, grinding, drilling, gouging, cutting, sawing on the basis of drawing documentation supplied by individual customers.

We also ensure the finalization of mechanical parts in areas of surface treatment and heat treatment through cooperation services from carefully selected suppliers.

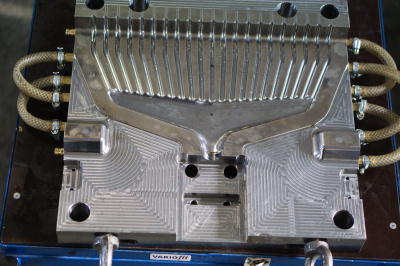

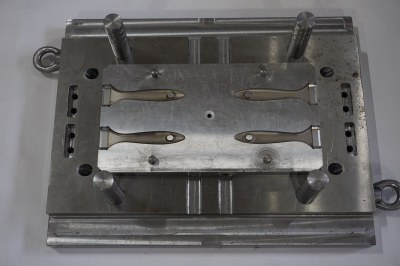

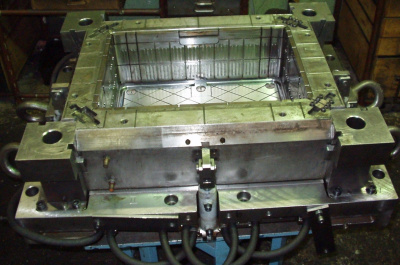

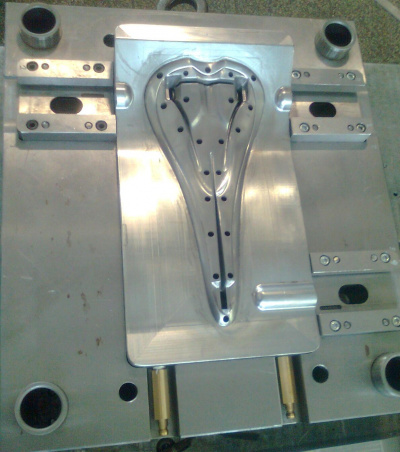

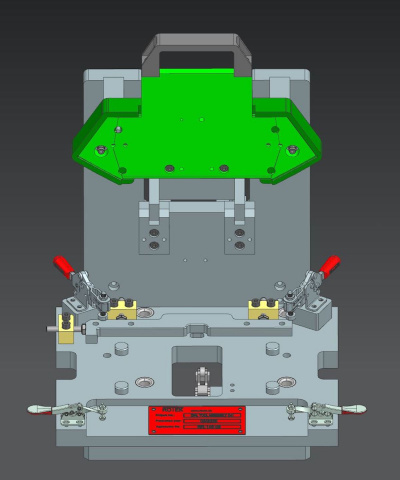

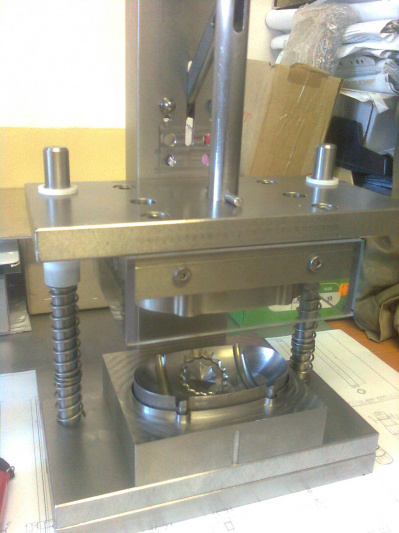

Production of injection molds

Our offer for the production and repair of molds grows in direct proportion to cattle. For this reason, we ensure the constant modernization of the machine park with an emphasis on quality and in order to maintain the current standard in the production of high-precision components.

We realize the production of injection molds for plastics and light metal alloys according to the requirements of our customers. We have a special professionally advanced team that will also design the mold from the part model. The actual implementation of production is preceded by structural and technological design in 3D programs. The size of molds and tools is limited in terms of technological possibilities. The maximum dimensions are 850 x 850 mm and the weight is about 2.0 t. In the production process, we also make extensive use of 5AX fully continuous milling up to a weight of 1.5 tons.

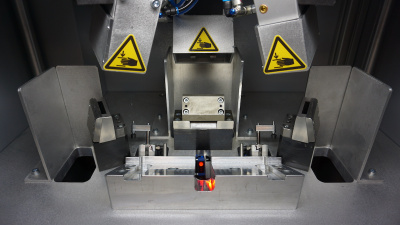

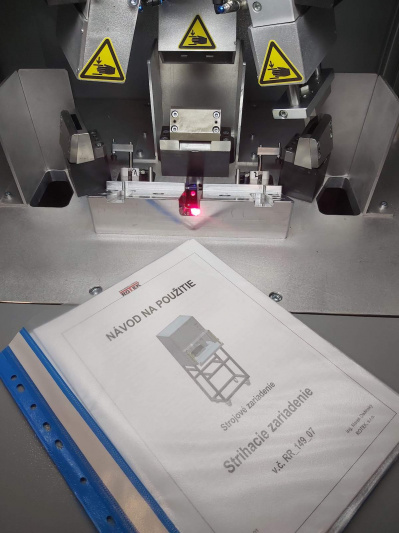

Production of single-purpose machines

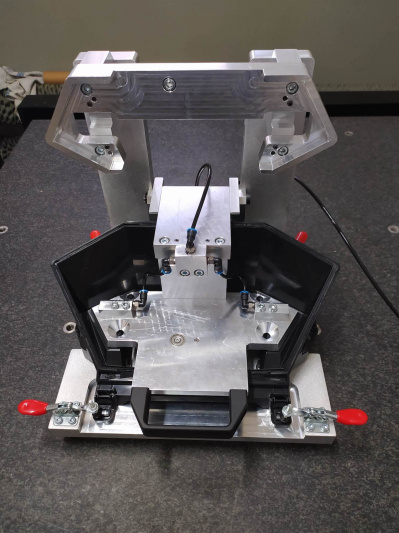

We have expanded our offer to include the development and production of single-purpose machines. Implementation includes complete services necessary for the design of 3D design to the production itself and tests in-house. We hand over the completed machine with certification and the necessary revisions.

Production automation is one of the other means to increase the efficiency and quality of the production process. We provide complete design and production of single-purpose machines that can meet real requirements but also perform presence control with regard to safety at work. Made single-purpose machines work in semi-automatic and automatic mode.

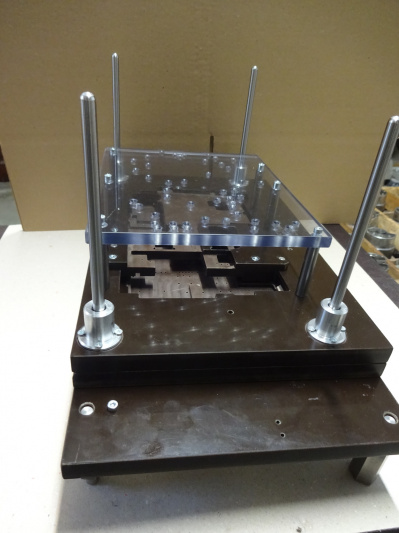

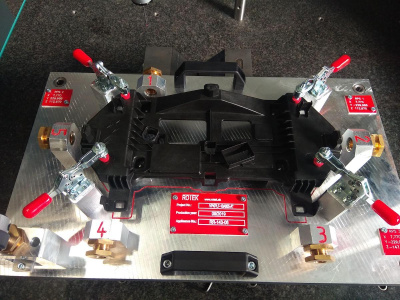

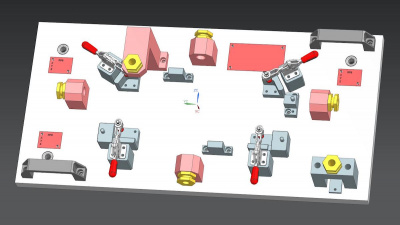

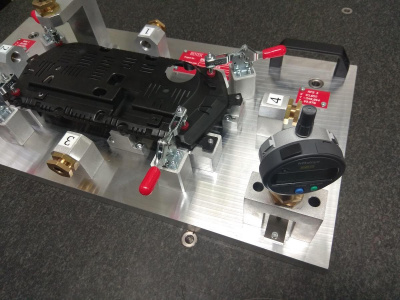

Production of measuring, assembly and welding jigs

In this area, we provide services for customers from 3D design to the production of finished products. We solve all the necessary requirements during the project at our own expense, which allows us to offer flexibility in the entire process of development and production of products.

We manufacture measuring, assembly and welding jigs to order with a specific specification. We realize their production from 3D designs to the actual production of the complete set.

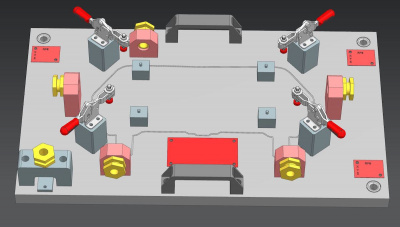

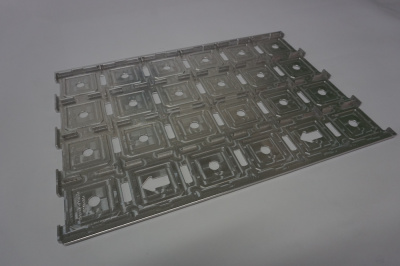

Production of bending and cutting tools

We carry out production in both simple and progressive combined design. As with each of our activities, we create a 3D design and then make the required tool.

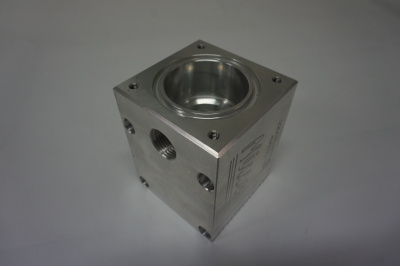

CNC machining

Thanks to modern technological equipment and rich several years of experience, we can produce dimensionally different and complex components. Customer requirements are a priority for us, we can provide professional advice in solving the technology of production of demanding parts. We are constantly innovating the technology park and, in terms of processing quality, we also invest in 5 axes of milling machine tools with direct measuring.

We have a wide range of machinery. We carry out production on CNC lathes with driven tools and CNC milling machines of 3-axes and 5-axes and horizontal 3-axes.

Electroerosive machining

In the production process, taking into account details and precision, digging and cutting is an integral part of our offer. EDM technology allows extreme precision to be achieved in the production of incredibly fine parts at very high cutting speeds. As there is no contact between the workpiece and the cutting tool, EDM allows even very small parts to be cut.

Use an electric spark to cut into a range of conductive materials from aluminum and copper to graphite. In processes for machining expensive materials, EDM has the advantage that it produces virtually no waste.

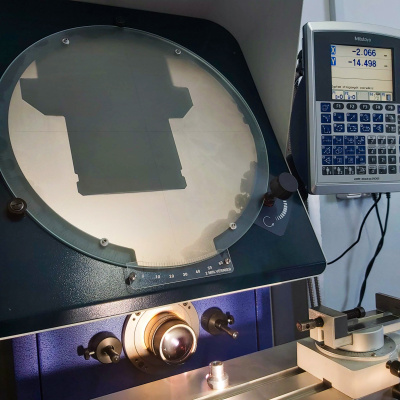

Control and measurement

In the production process we use progressive technological procedures and the whole process is under the supervision of the control and measurement department. In terms of complexity and resulting accuracy, we bet on the purchase of a quality 3D meter Wenzel LH 87.

The inspection and measurement department is part of the production process and checks all dimensions multiple times to minimize inaccuracies.